The BluePump is very reliable and therefore it does not need spare parts all the time as most other handpumps do… This means that the BluePump is in fact very economical to operate, at a fraction of the cost of the standards handpumps presently in use in Africa.

Nevertheless, we advise a service visit every year by a qualified local Pump Mechanic to check on all nuts & Bolts and the Pumping System.

On top of that: it is good to know that you can always get any part that you may need.

Spares are available from your local country dealer, or from a BluePump NGO partner, or directly from Boode B.V. We are known for a quick end quality service because we know that pumps need to work, every day.

On each BluePump, you will find our international service mobile nr. +31 6 236 686 15 that you can SMS, WhatsApp or call in case you need urgent assistance or spare parts. Actually, we hardly receive any calls, which indicates that most BluePumps are functioning all over Africa.

On the front side of the BluePump, you will find in the cap 4 small holes, here you can attach with rivets your own project info or any message or advertisement that you may like. You can order an aluminum plate with 4 holes and rivets for that purpose when you buy your BluePump.

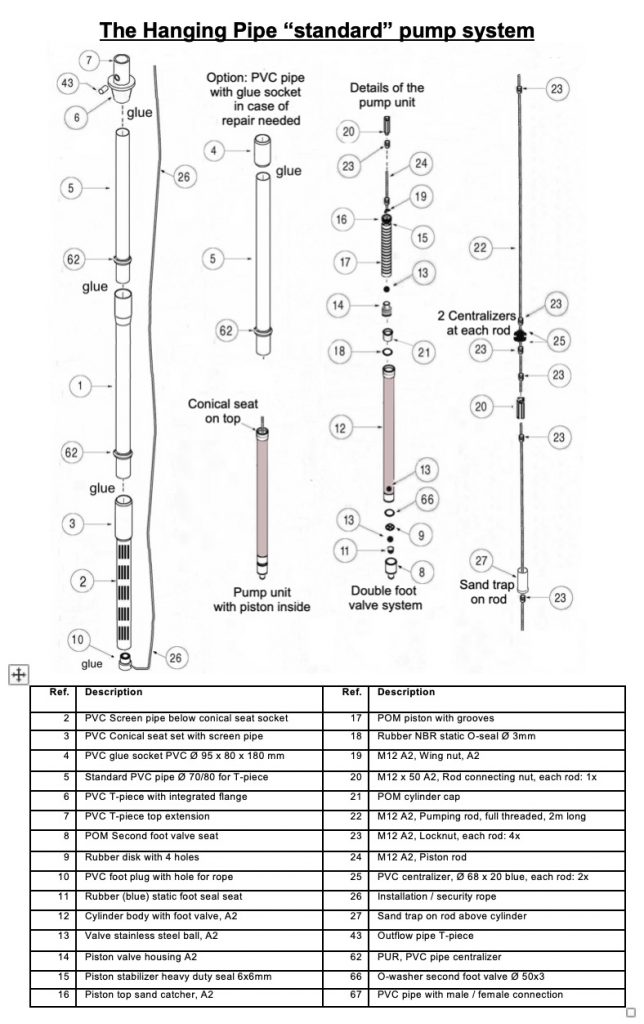

In the technical drawing below you find a list of all current parts of the BluePump model 2019. In case you have an older type, don’t worry, all new parts are compatible with the older parts.

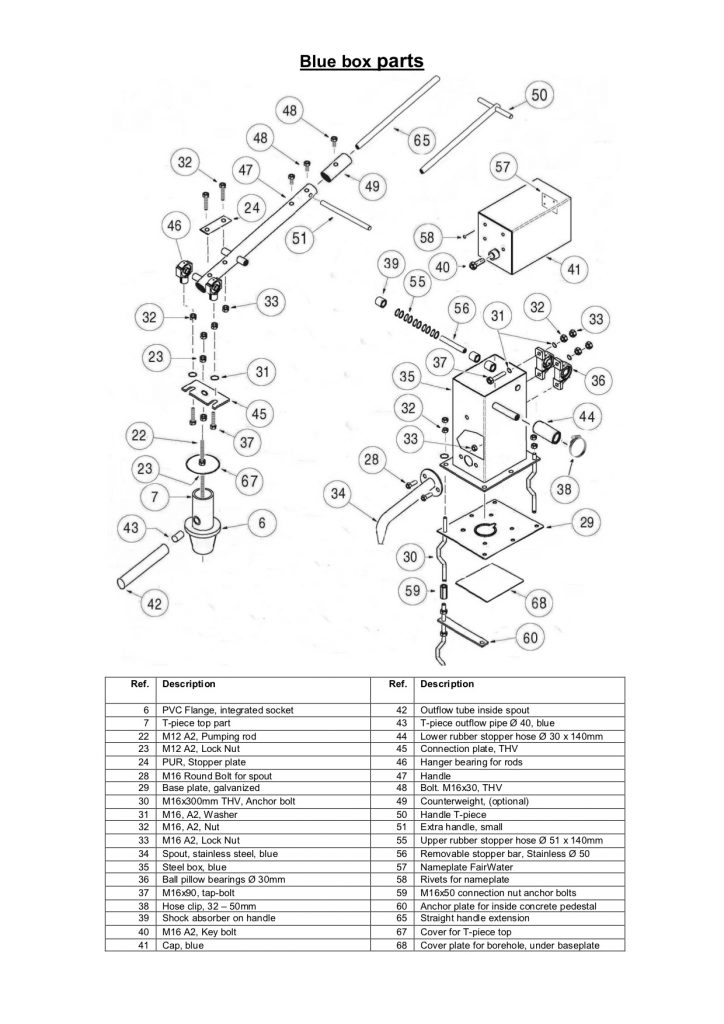

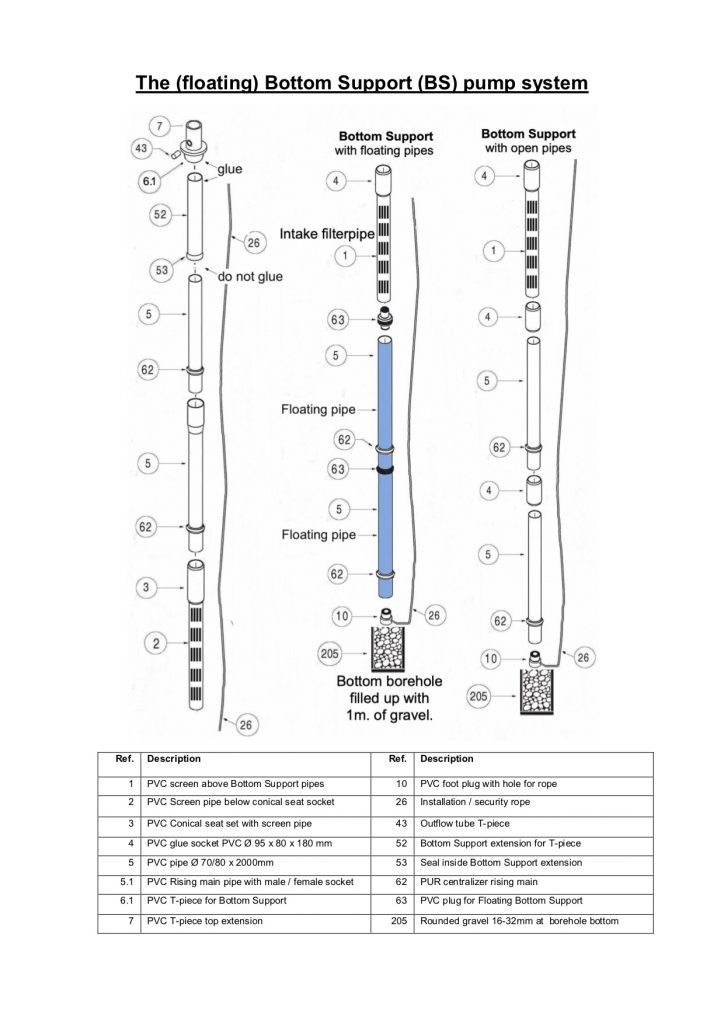

BluePump parts and upgrades

From time to time we improve BluePump parts or add new parts, based on feedback from the field. Over the last years some of the main improvements are:

- #3 The Conical Seat Socket; the conical seat is now pre-glued inside a special longer socket, which is pre-glued to a screen pipe.

- #5 The PVC pipe; In 2011, we reduced the length of the PVC pipes, (and the rods…) from 3m to 2m. This was done to make the total pipe structure stronger. Hanging PVC pipes are flexible and stretch during pumping, which can ultimately cause cracks. By reducing the length, combined with a glued connection every 2m, the stretching of the pipes during pumping is considerably reduced.

- #8 Second Foot Valve; It is screwed to the bottom of the stainless steel cylinder #12, however, when stainless steel is screwed into stainless steel, the threading can get stuck when there is sand or silt in between. Therefore our second (safety) foot valve is made from the very strong material Ertalite.

- #15 The piston stabilizer; The purpose of this is to keep the piston centered and at the same time, and offer additional pump pressure. It is made from high-quality material that is normally used to make the shaft of a motorboat watertight. We recommend installing this directly below the sand trap #16.

- #22 The rods: Originally, we started with traditional 9mm rods of 3m long with a rolled on threading on each side, but we found that this gave too many vibrations during pumping, especially in deep boreholes, which could ultimately lead to broken rods. Therefore we changed to fully threaded rods of 2m and increased the diameter of the rods to 12mm. The obvious advantage is that you can now cut the rods anywhere and always have a threaded connection. The advantage is that In the rare case a rod breaks for whatever reason, you do not need to find a new rod, you just fish the rod out and connect it again with a nut #20.

- #25 The rod centralizer; Centralizers can wear out in deep boreholes due to the fact that deep boreholes are not straight. The early models up to 2009 of the BluePump had a white centralizer that was in fact too strong, so with time, it could damage the inside of the PVC pipes with time in curved boreholes. This new one has the color blue and is made from a material that has a slightly lower hardness than PVC, so it can not damage the PVC pipe. The advantage of this material over rubber is that it has a very low glide resistance and does not wear out that fast as rubber, so it last much longer. There are 2 on each rod that fit into each other. If one side wears out, the centralizer can be turned around 90 degrees to make it again a complete round centralizer. Another advantage of this new blue centralizer is that this special material is lighter than water, so when small parts may come off with time, they do NOT sink down as is the case with rubber centralizers, which can get stuck in the pumping system of the pump. Instead, these small parts will flow upwards and flow out of the pump with the pumped water.

- #27 Sand-trap on the rods; During pumping it is possible that silt and sand will go into suspension and will be pumped up. When the pumping stops, this will slowly go down in the rising main and may accumulate on the top of the piston. To avoid this and to avoid that material from the top will enter into the cylinder, this Sand-trap can be installed on the lowest rod, above the cylinder.

- #29 Base Plate; The old model consisted of only 4 holes on the corners like most handpumps have, but we found that in deep boreholes that a strong connection of the metal box with the concrete is very important, so we have now 6 anchor bolts. Older models also had 2 parts made from POM but these are now replaced by 1 part only, made from galvanized iron. It has 4 little 13mm diameter holes inside that fit the construction holes of the Afridev and India MK pumps. This makes replacement of these pumps with the BluePump easy and fast. The Base Plate also serves as a mold to position the 6 anchor bolts in the concrete pedestal.

- #30 Anchor Bolts; The traditional anchor bolt comes with a hook. We added a new type that has a “bayonet” curve to secure it in the concrete.

- #34 The Spout; The new spout is now from Stainless Steel 304; this was needed because we found that is some situations the groundwater is very aggressive and the spout started to rust in these extreme conditions.

- #41 The cap; The new cap is also made from stainless steel 304 because we found that similar to the #34 Spout, in some cases very aggressive water could make the cap to rust.

- #50 T-piece; Adjustable handle part with the possibility of adding a counterweight #49. This part can also be replaced with an extendable T-piece #65.

- #51 Small handle; The new 2019 model standard handle is a bit shorter to allow easy pumping in shallow boreholes. To have a better grip, we added a small bar that can be pushed perpendicular to the end of the handle.

- #59 Anchor connecting nut M16; This was added to connect the new “bayonet” anchor bolts together to make it longer and to add a plate #60 to it to make the anchor construction stronger. This was needed for very deep boreholes because we found that the high stress on the anchor bolts could give problems with the concrete.

- #60 Anchor strip; This was added to the anchor system to get a better grip for the anchor bolts in the concrete. We recommend using one strip only at the side of the spout.

- #61 T-piece protection; This is a strong flexible rubber disc that can be pushed over the top part of the rods to protect the inside of the rising main from dust or parts falling in.

- #62 Pipe Centralizer; There is always some space between the PVC pipes (that have an outside diameter of 80mm) and the borehole casing, which is often 4-1/2″ with an inside diameter of about 115mm. Especially in the case of a “hanging pipes” the PVC pipes can move laterally and vertically due to pumping, which can cause fatigue in the pipes and ultimately may cause minor cracks in the PVC. These special centralizers avoid that and improve the longevity of the system.

- #63 Plug Bottom Support; With this plug, you can change the “Open” Bottom Support PVC pipes into “Closed” (floating) sections of each 2m long. This means that these closed pipes will float in the borehole, and therefore reduce the pressure on the #10 Bottom Plug, and avoid that the total column of PVC pipes will press too much on the bottom plug of the borehole casing. The floating of the Bottom Support pipes will also make the installation in deep boreholes also more easy because as soon as these pipes will be at the water level in the pump, they will reduce the total weight of the pipes.

- #64 Cover plate for the borehole. When the concrete plinth is made and the baseplate #29 is on top of the plinth, this plate can be put between the base plate and the concrete to cover and protect the borehole awaiting the installation of the pump body.

- #65 Extendible T-piece, to be used if people prefer to pump with a T-piece.

- #66 O-ring between the extra foot valve and the cylinder.

- #67 PVC pipe D70/80 x 2000mm with male / female glue connection.

- #68 Gravel base in the borehole; In the bottom Support option the pipes go down to the bottom of the borehole. Normally, this bottom has a strong plug to close the borehole casing pipe. However, when the borehole is old, often a layer of silt is present in the bottom. To avoid that the Bottom Support pipes will slowly sink in this silt, we recommend to fill-up the bottom of the borehole with rounded gravel (size 16-32mm) which will provide a solid base for the pipes.

Options that are not standard - Floater for rods; This is an option for very deep boreholes to make the pumping considerably lighter by about 50%. These floaters are simply put over the rods and secure with a #Locknut. During pumping, each time the total column of water needs to be lifted. They replace the water by air, therefore the pumping at 90m deep will feel the same as 50m deep. This also improves the longevity of the pump system and bearings.

- Handle with T-piece with extra-wide base; This makes pumping with 2 persons easier because they can stand side by side, in the case of a deep installation.

- Water Hose connection; This makes the water coming out of the T-piece in a more concentrated flow, and also enables to connect a standard water hose of 25mm diameter to the pump. With a hose, it is not necessary to place a jerry can or container directly below the spout and can also be used to irrigate a small vegetable garden next to the pump.

List of current BluePump spare parts

Below you find several technical drawings that clearly indicate all parts of the BluePump in their position. In case you need one or more parts, just send us the number and description of the parts that you find in this drawing.

Please note that the PVC Flange is not anymore multiple purpose for the hanging as well as for the Bottom Support system. The hanging Flange #6 is now only for the hanging installation and the Bottom Support Flange #54 is now pre-glued to the longer (80cm) Bottom Support sleeve #52. It was needed to make the BS sleeve longer to compensate for eventual sinking in of the BS pipes.

Also, the BS sleeve is not anymore put in the Cap #41 together with the small materials and bearings, but comes separete with the Pump items.

Composed items

The following items come already pre-glued from the factory to avoid confusion and to speed-up the installation; these combination have their own specific nr.:

#110 = (#3 + #2) the conical seat pipe;

#112 = (#52 + #53 + #54) the Bottom Support sleeve.